- +86 136 65744767

- 09:00 AM - 5:00 PM

In the realm of agricultural and industrial logistics, the choice of securing materials during transportation is crucial. Traditional methods such as twine or rope have long been the standard, but emerging as a formidable alternative are baling straps. These sturdy and cost-effective straps offer enhanced resistance and strength, particularly when bales or waste are in transit.

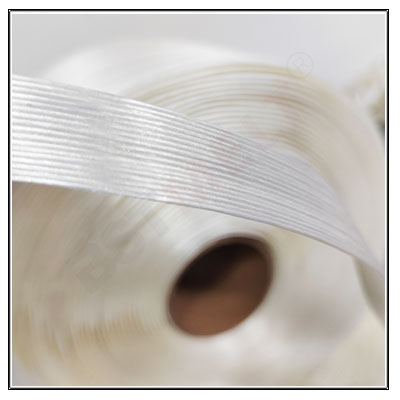

Baling straps, also known as bale straps or banding straps, are made from durable materials such as polypropylene or polyester. Their construction ensures they can withstand considerable pressure and tension, making them ideal for securing bulky or heavy loads. Unlike twine or rope, which may degrade over time or weaken under strain, baling straps maintain their integrity, providing a reliable means of containment during transportation.

One of the primary advantages of baling straps is their superior strength-to-weight ratio. Despite being lightweight, these straps boast impressive tensile strength, enabling them to withstand the rigors of transportation without compromising on security. Whether used to bind together hay bales on a farm or secure industrial waste for disposal, baling straps offer peace of mind by preventing shifting or spillage during transit.

Moreover, baling straps are highly versatile, accommodating various shapes and sizes of loads. Their adjustable nature allows for custom fitting, ensuring a snug and secure hold regardless of the cargo dimensions. This adaptability makes them indispensable in industries ranging from agriculture and recycling to construction and manufacturing.

From an economic standpoint, baling straps present significant cost savings compared to traditional alternatives. Their durability means they can be reused multiple times, reducing the need for frequent replacements. Additionally, the efficiency of baling straps in securing loads minimizes the risk of damage or loss during transit, translating to lower overheads for businesses.

The environmental benefits of baling straps further underscore their appeal. Unlike twine or rope, which may contribute to plastic pollution or require natural resources for production, baling straps offer a more sustainable solution. Many are made from recycled materials, and their reusability helps minimize waste generation, aligning with the principles of eco-friendly practices.

In recent years, the adoption of baling straps has surged as industries recognize their efficacy and cost-efficiency. Agricultural operations, waste management facilities, recycling centers, and logistics companies are among those embracing this innovative solution for secure transportation. As the demand for reliable and sustainable packaging continues to grow, baling straps are poised to play an increasingly integral role in modern supply chains.

In conclusion, baling straps represent a commendable advancement in the field of cargo securing, offering robustness, versatility, and cost-effectiveness. Their ability to withstand the demands of transportation while minimizing environmental impact makes them a preferred choice for businesses seeking reliable packaging solutions. As industries evolve, baling straps stand out as a testament to innovation driving progress in logistics and sustainability.

BSTSTRAP

No.30 building, Wuxing High-tech Venture Park

Huzhou City, Zhejiang Province,China

Whatsapp:+86 136 6574 4776

Monday to Saturday 9 am to 5 pm

hailey@bststrap.com

Send us your enquiry anytime!