- +86 136 65744767

- 09:00 AM - 5:00 PM

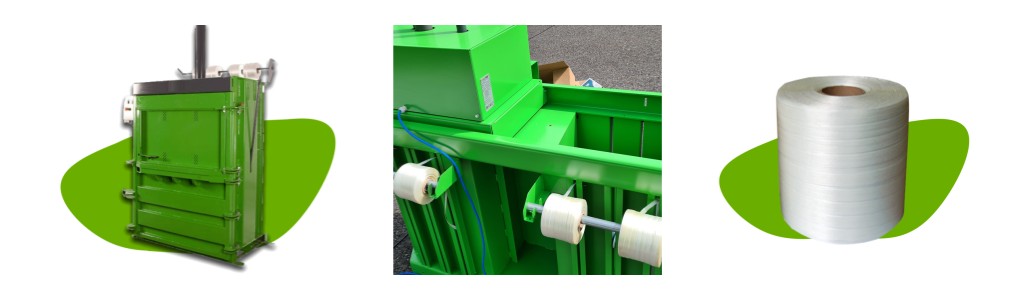

Baling Strap, otherwise referred to as hot melt strapping, has many advantages over conventional manually applied products such as steel straps, metal banding, rope, plastic straps and stretch film. Compared to these products bonded strapping is applied in a faster, safer and more cost-effective way. The Bale Press Strapping can be joined by a simple knot or used in combination with buckles, tools and tensioners, providing the most dependable joining systems. The strapping can be tensioned using manual or pneumatic tension tools.In the ever-evolving world of waste management, innovative solutions are constantly being developed to streamline processes and reduce environmental impact. One such breakthrough is the baling strap, a remarkable invention that has revolutionized the efficiency of waste compactors.

The baling strap, a strong and durable material, is designed to securely hold together compressed waste, resulting in denser and more manageable bales. This not only enhances the compactor's performance but also significantly reduces waste volume, making it an eco-friendly and cost-effective solution for waste disposal and recycling.

The introduction of baling straps in waste compactors has brought about a paradigm shift in waste management. By increasing the density of the waste bales, transportation and storage costs are reduced, thereby minimizing the carbon footprint associated with waste disposal. Furthermore, the use of baling straps has opened up new avenues for recycling, as the compacted waste can now be more easily processed and repurposed.

The baling strap's unique design and superior strength make it an ideal choice for waste compactors in various industries, including construction, manufacturing, and hospitality. Its versatility ensures that it can be adapted to different waste types, from card This not only enhances the compactor's performance but also significantly reduces waste volume, making it an eco-friendly and cost-effective solution for waste disposal and recycling.

The introduction of baling straps in waste compactors has brought about a paradigm shift in waste management. By increasing the density of the waste bales, transportation and storage costs are reduced, thereby minimizing the carbon footprint associated with waste disposal. Furthermore, the use of baling straps has opened up new avenues for recycling, as the compacted waste can now be more easily processed and repurposed.

The baling strap's unique design and superior strength make it an ideal choice for waste compactors in various industries, including construction, manufacturing, and hospitality. Its versatility ensures that it can be adapted to different waste types, from cardboard and plastic to organic waste and metal.

One of the key benefits of using baling straps in waste compactors is the significant reduction in waste volume. This notboard and plastic to organic waste and metal.

One of the key benefits of using baling straps in waste compactors is the significant reduction in waste volume. This not only saves space in landfills but also reduces the need for frequent waste collection, thus lowering operational costs. Moreover, the denser bales make it easier to handle and transport waste, further enhancing operational efficiency.

Another advantage of baling straps is their durability and longevity. The high-quality material used in their manufacture ensures that they can withstand the rigors of daily use without compromising on performance. This, in turn, leads to reduced maintenance costs and increased equipment uptime.

In conclusion, the introduction of baling straps in waste compactors has revolutionized the way we manage waste. By increasing efficiency, reducing waste volume, and promoting recycling, this innovative solution has become an indispensable tool in the global effort to combat environmental pollution and promote sustainability. As we continue to search for greener and more effective ways to manage our waste, the baling strap stands as a shining example of what can be achieved through ingenuity and commitment to environmental stewardship.

BSTSTRAP

No.30 building, Wuxing High-tech Venture Park

Huzhou City, Zhejiang Province,China

Whatsapp:+86 136 6574 4776

Monday to Saturday 9 am to 5 pm

Send us your enquiry anytime!